Money loss

Loss of product due to wine evaporation results in loss of sales at the end of the year

Time loss

Performing fillings without proper planning can lead to a large waste of time and labor.

Wine quality

Opening a barrel to check its condition can adversely affect the quality of the wine: during a filling, 80 percent of the oxygen enters the barrel.

Nova Stark has developed a set of services to monitor the cellar environment and minimize losses

Nova Stark has developed a set of services to monitor the cellar environment and minimize losses

Arya

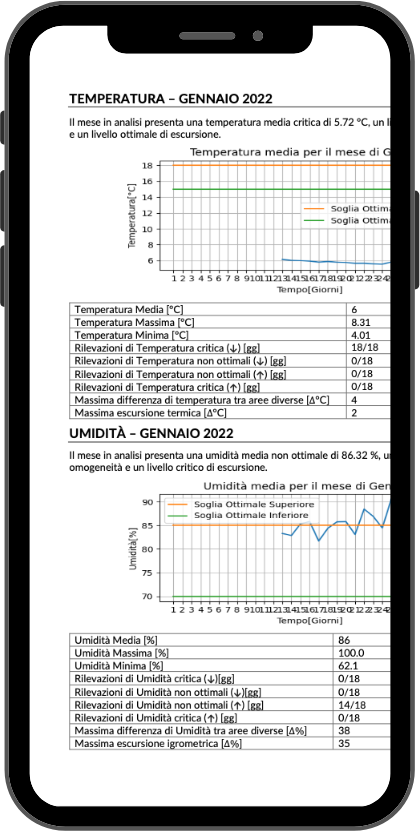

The Arya system consists of non-invasive, easy-to-install sensors that monitor cellar humidity and temperature with extreme accuracy.

Lygnum

Lygnum takes care of direct monitoring of the barrel: sensors in the cork capture external temperature and humidity, while internally they record evaporation and temperature levels of the wine.

PLATFORM

All data collected in real time from the always-on sensors can be easily accessed on our platform. From any device you have access to customized graphs, heat maps, barrel log and activity log.

REPORT

Through experience and numerous case studies, we at Nova Stark provide customized reports that give insight into the condition of your winery, which are essential for making the right decisions and optimizing production.

Once we receive the floor plan, we take care of everything: in the first inspection we familiarize ourselves with the winery and study the best application for our sensors. The goal is to offer a customized solution based on the winery’s own needs